The Takeaway: Allied’s newest bike is the BC40, a 120mm carbon full suspension trail bike with a race edge. It is light and offers very competitive performance even in the face of very stiff competition. And it’s made right here in the USA.

- Manufactured, painted, and assembled in Rogers, Arkansas.

- 120mm rear travel designed around 120mm forks. With fork and shock swap, can be set up with 100mm travel.

- Five customizable complete builds start at $7,625.

- Claimed frame with shock weight: 1,940 grams (size large).

- 73mm threaded bottom bracket shell.

- Fits two bottles inside the front triangle.

Price: $12,445 (as ridden)

Weight: TBD

Allied is making moves. Founded in 2016 to bring carbon-fiber frame production to the USA, the company’s drop bar bikes like the Alfa, Able, and Echo have impressed us. But the newest Allied is their most ambitious project since the company’s founding. The BC40 is a carbon fiber full suspension mountain bike frame made in-house, in high volumes, and in the USA. Which makes it an extremely rare and potentially important frame.

I recently flew to Bentonville, Arkansas to watch the BC40 get manufactured firsthand and was the first person outside of Allied’s family to ride this important new bike.

Allied BC-40—Made In Rogers Arkansas

What makes the BC40 special is where it’s made. When I asked Allied’s Sam Pickman, Allied’s director of product, why it is important to manufacture the BC40 in the USA he said succinctly, “Our mission is to make the best, and the only way to make the best is to do it yourself.”

The BC40 is laid up, finished, and assembled in-house, a few feet from Allied’s product team. That makes it one of a tiny number of carbon full suspension frames made in the United States. —the Ibis Exie and Guerilla Gravity’s thermoplastic frames are the others. CEO Drew Medlock told me, “Doing it here in the US gives us full control of every step of the process from building tooling, testing, iterating, and manufacturing. We know every piece of material that goes into the frame and every step of the process. That equals a better final product, and something we are proud to put our name on.”

The Allied factory in Rogers is clean, well organized, and cramped. It is clear that Allied needs more space, not only to keep up with demand but also to achieve their ambitious goals. They want to be bigger and make more bikes, and Medlock told me they are looking for a larger facility in the area. Currently, Allied can make up to 50 BC40’s a month. That’s 50 mountain bike frames in addition to their current monthly drop bar frame production numbers. While that is a pittance compared to the huge frame factories in China, Vietnam, or Malaysia, Allied is the only carbon frame factory in the United States that comes close to something you could call high-volume production. The frames are laid up, molded, finished, and assembled in-house, and many of the aluminum parts (like the swing link) are machined in-house also.

Everything about Allied’s manufacturing is very ordinary. They don’t have any secrets. In fact, they gave me free rein to wander the factory unsupervised for as long as I wished and take pictures and videos of anything I wanted. I’ve never been able to do so at any carbon manufacturing facility I’ve previously visited. Typically, carbon factory tours are highly supervised with severe restrictions on my ability to capture photos or video. But what makes the BC40 unique isn’t in the development process, manufacturing method or suspension technology, but that they’re making them here, in the US.

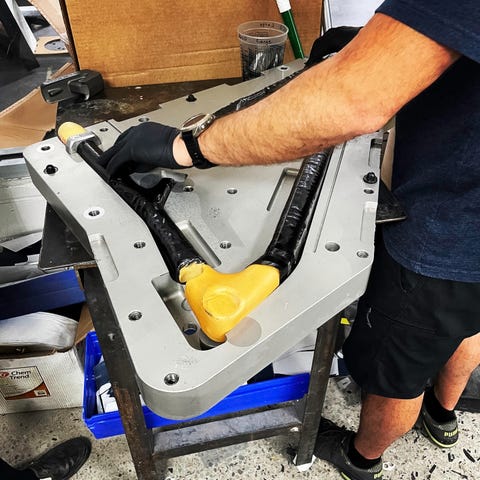

What I saw at Allied is similar to other factories’ thermoset-carbon production methods. The frames start life as rolls of prepreg carbon sheet. They’re laid on a table where a laser cuts the 517 individual pieces of carbon that make up the frame. Some pieces are pre-stacked in the cutting room before all the carbon bits are collected into a bin. The bin goes into the assembly room where workers lay up the carbon over silicon bladders.

Interestingly, Allied uses uncooked couscous as filler to keep the bladders rigid during layup. It’s cheap, abundant, and biodegradable, said Pickman. Once built, and drained of couscous, the subassemblies are placed into in-house-machined aluminum molds. There is one mold for the front triangle, while the rear is molded as two pieces that are bonded together later. The mold is closed and bolted together, air lines are hooked up to pressurize the bladders, and the mold is then slid into a heated press where it is squeezed with 25 tons of pressure.

After curing, the frame parts come out of the mold and begin the last phase of their journey. Molding flash gets removed and interfaces like the head tube, bottom bracket, and bearing seats get cleaned up. Then a large crew starts prepping the frame for paint. This process involves a lot of sanding, inspecting, and touching the frame under high-intensity lights to create a smooth and even surface for paint.

Pickman, Allied’s director of product, proudly states that the frames come out of the mold needing little filler to smooth their surface. The large team of finish workers (and the intensive work they do) is not to cover up any flaws—perceived or otherwise—but to set the stage for a deep and high-quality paint job that buyers of a premium carbon frame expect, he explained.

Once it clears prep, the frame moves to paint. Allied offers several stock colors, and a handful of upgraded finish options (Allied’s graphics are masked and painted, not stickers) but can also cook up custom colors and finishes—for a price, of course. Allied-sponsored Payson McElveen’s BC40 with arresting fade and splatter scheme—the appeal of which divided Bicycling’s gear team—is one example of what the company can do.

Allied BC40 Travel—Fast, and Faster

Allied designed the BC40 as a 120mm frame and around a 120mm fork. That puts it in the fast trail bike category and up against some stiff competition like the Specialized Epic EVO (which was Allied’s benchmark during BC40 development), the Trek Top Fuel, Spot Ryve 115, Cannondale Scalpel SE, Transition Spur, Revel Ranger, and Santa Cruz Blur TR.

But Allied built the BC40 to be more than a one-travel platform. With a different shock, the BC40’s rear travel can be set to 100mm. And coupled with a 100mm fork the platform takes on a more XC-race feel. Allied’s sponsored athletes Payson McElveen and Lea Davidson will race the BC40 in 100mm mode for many of their events, including the Leadville 100.

Allied BC40—The Spanish Connection

For help with its first full suspension bike, Allied received help from Cero Design. Based in Barcelona and led by former World Cup downhill racer Cesar Rojo, Cero works with several brands in the cycling space—some past clients include Mondrakerand Intense—as well as designing and building the striking Unno bikes.

Medlock said, “We wanted to use Cero’s design and engineering resources to help us hit our goals of making the best possible bike. It was a highly collaborative process, but they were in control of the design and kinematics. We steered the direction of the bike from a high level, giving design inspiration and ensuring that it fits in the family aesthetically, and letting them know exactly how we wanted the bike ride which dictated the kinematic. They used their years of experience and resources to give us the 3D models which we turned into the final product.”

The BC40’s suspension is a straightforward single pivot with swing link and flex stays. This is the same system you will find on a Specialized Epic, Cannondale Scalpel, Transition Spur, and in fact many other bikes. It might not be flashy, but it is an effective and proven system for shorter-travel bikes.

Allied BC40—Weights And Features

Allied quotes a frame-only weight of 1940 grams (for a size large) with a RockShox SID Luxe shock. That is a bit heavier than the Specialized S-Works Epic Evo frame which weighs around 1660 grams with shock. Complete bike weights will vary based on paint and parts, but as an example, Payson McElveen told me his size large BC40 with heavier high-country build—dropper post and heavier tires—comes in at 24.2 pounds but drops to 21.7 lb. with his XC race setup (rigid post, lighter tires).

Allied stuck with tried-and-true specs for the BC40. You will find a 73mm threaded bottom bracket, molded cups for integrated headset (the Chris King Dropset 3 fits) and tapered steerer, boost rear spacing, post mount for 160mm rear disc rotor, 31.6mm seatpost, and a SRAM UDH derailleur hanger. Hoses and housing run internally, and the BC40 has provisions for an internally routed dropper post as well as a remote shock lockout. Plus, there is room for a 2.4-inch-wide rear tire with four millimeters of clearance on all sides. And in a move sure to make racers very happy, the BC40 fits two bottles inside the main triangle.

Allied BC40—Geometry

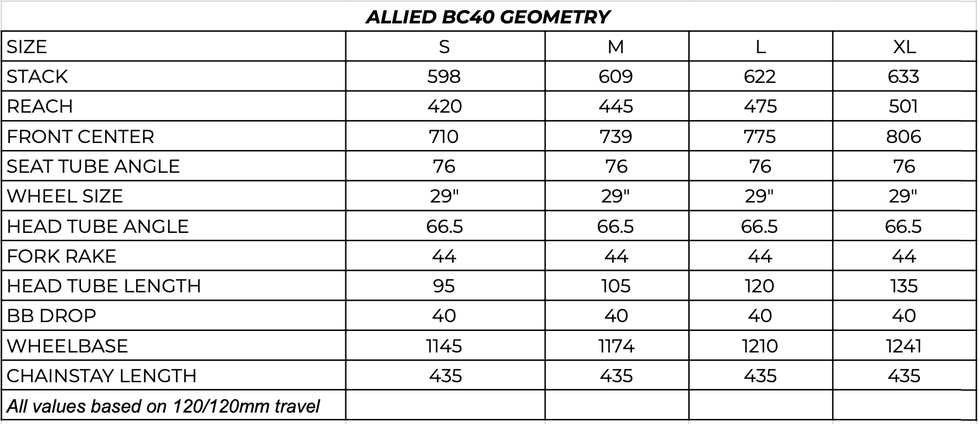

Allied offers the BC40 in four sizes—small through extra-large—with all sizes rolling on 29-inch wheels. The geometry overall is modern but not radical, with Allied keeping it close to proven competitors like the Specialized Epic Evo. The highlight geometry numbers at 120/120mm travel are 76-degree seat angle, 66.5-degree head angle, 40mm of BB drop, and 435mm chainstays.

Allied BC40—Builds and Pricing

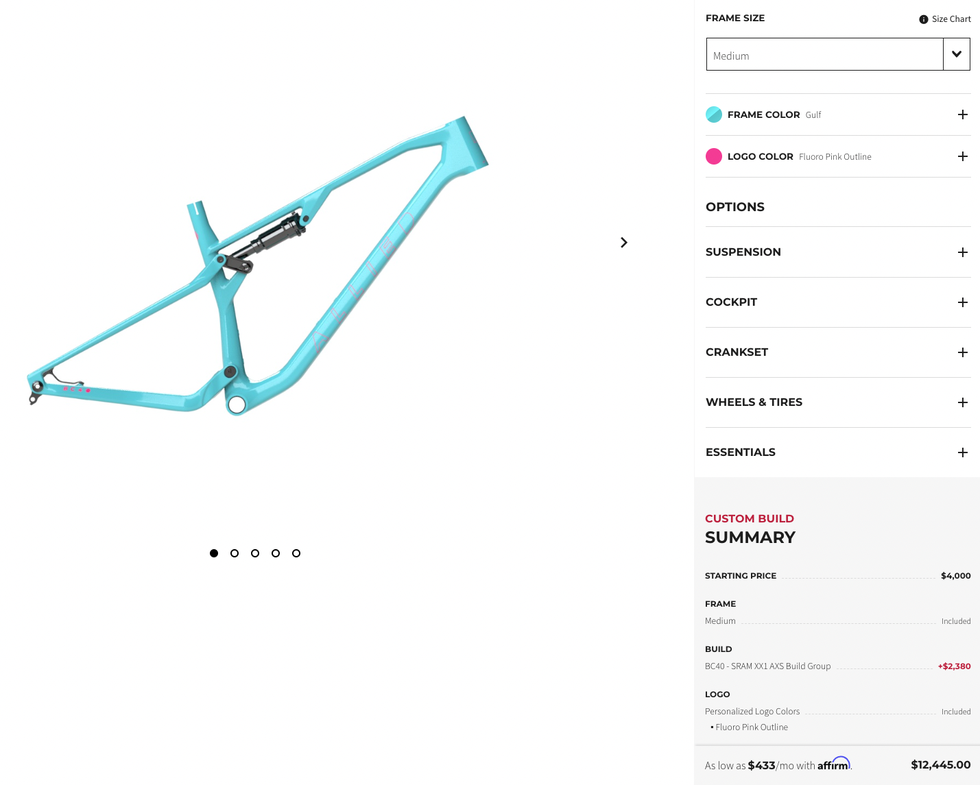

Allied begins accepting orders today for the BC40, with the first deliveries arriving in customers’ hands about 12 weeks later. There are five complete options, starting at $7,625 for a Shimano XT build and topping out with a SRAM XX1 Eagle AXS build at $12,115. In between are SRAM GX Eagle AXS ($7,995), Shimano XTR ($9,950), and SRAM X01 Eagle AXS ($10,755) models.

Those prices reflect the BC40 with Allied’s stock parts picks, matte black paint, and silver logos. However, Allied lets riders customize almost every part of the build. Multiple upgrade options exist for frame and logo colors, suspension components, headset, bar and stem, saddle, seatpost, and wheels. In addition, Allied also offers optional accessories like Arundel carbon cages and Garmin Rally power meter pedals.

If you prefer to play product manager at home and build up your own BC40, frameset prices start at $5,590 for the frame with shock and fork. You get your choice of a RockShox Ultimate or Fox Factory suspension package and a Cane Creek Hellbender 70 Lite headset.

Allied BC40—First Ride Impressions

I flew to Bentonville, Arkansas to watch the BC40 getting built in Allied’s factory, and a first ride on the area’s famous trails. The trails that helped shape the BC40; the trails the BC40 was designed for. It was not a long ride, and I was on a 120mm-travel large. The medium would be a better fit for me, but no mediums were built at the time of my ride. So, these are initial impressions, and I will follow up with a full review on the BC40 when a medium test bike (which is in the queue) arrives for me to ride on my home trails in Durango.

The BC40 is a sprightly bike, adjacent to a modern cross-country racing bike. It is too quick and too fast to be compared to the typical trail bike, but in 120mm mode, it’s not quite as explosive as a pure XC race bike. The suspension is tuned to the firmer end of the spectrum, giving it a responsive and efficient feel on the pedals with a supportive spring curve that stays high in the travel on climbs. When I got out of the saddle to attack a steeper section, I felt little softness in suspension and no wag in the frame either. Rear traction is good, with just enough sensitivity off the top to stick the faster rolling 2.4-inch Maxxis Rekons to the trail. The 66.5 head angle provides a good balance between helping to keep the front end hooked up and tracking true on climbs, while also allowing for good manners on flatter trails and descents.

While the BC40 climbed very well, I was more impressed with how well it handled descents. I threw myself down some rock-strewn downhills, a few jump lines, and even sent it off a decent-sized road gap. The BC40 took it all in stride. The handling is intuitive, and the rear end takes up bumps predictably. The ride is more of a skip over the top of bumps than flow through the bumps but has plenty of progression in reserve for when you come into a chunky section a bit too hot (guilty!). The frame’s stiffness is impressive given the bike’s low weight. I’d say the frame feels slightly more damped than average, but it never suffered from a lack of feedback.

Time will tell, but I am anticipating that the medium frame will feel livelier and a bit sharper to me than this large. It felt great when plowing chunk, but just slightly diluted in tighter and slower terrain. Basically, it felt like the bike was a bit too big for me and was too stable for my liking.

Overall, the BC40 offers incredibly competitive performance in a no-fuss package that is made right here in the US of A. When I review overseas-made carbon bikes I get messages and see a lot of social media chatter from riders who say they wish there were US-manufactured options to buy. Well, Allied called your bluff and it’s now up to you. If you want Allied to keep making bikes in Arkansas—if you want to see more US-manufactured carbon bikes—you know what you need to do. Don’t make the BC40 a brown diesel manual station wagon.

A gear editor for his entire career, Matt’s journey to becoming a leading cycling tech journalist started in 1995, and he’s been at it ever since; likely riding more cycling equipment than anyone on the planet along the way. Previous to his time with Bicycling, Matt worked in bike shops as a service manager, mechanic, and sales person. Based in Durango, Colorado, he enjoys riding and testing any and all kinds of bikes, so you’re just as likely to see him on a road bike dressed in Lycra at a Tuesday night worlds ride as you are to find him dressed in a full face helmet and pads riding a bike park on an enduro bike. He doesn’t race often, but he’s game for anything; having entered road races, criteriums, trials competitions, dual slalom, downhill races, enduros, stage races, short track, time trials, and gran fondos. Next up on his to-do list: a multi day bikepacking trip, and an e-bike race.